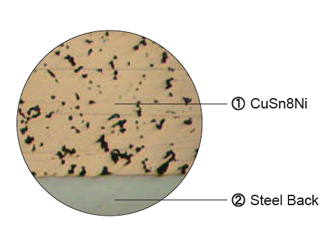

At the core of bimetal bearings lies a unique construction featuring two layers of different materials. Typically, the bearing's backing layer is made of a strong and durable metal, such as steel, chosen for its load-bearing capabilities and structural integrity. The inner layer, also known as the lining or bearing surface, comprises a softer, low-friction material, often based on bronze or other self-lubricating alloys.

Sinter lead-free bronze powder, provides bearing performance, have good wear resistance and excellent load carrying capacity.

Steel backing, provides exceptionally high load carrying capacity and excellent heat dissipation.

Steel backing lead-free bronze layer provides high specific loads, excellent fatigue strength under dynamic and shock load application, superior performance under oscillating movement, indents and grooves in the bearing lining provide a reservoir for grease and thus allow extended re-greasing intervals. Lead free bearing lining can meet EC directive of 2000/53/EC.

| Tech. Data | |||||

|---|---|---|---|---|---|

| Max. load | Static | 250N/mm2 | Alloy hardness | ≥HB70 | |

| Dynamic | 140N/mm2 | Temp. | -40°C~+250°C | ||

| Max. speed (Lubricated) | 2.5m/s | Friction coefficient | 0.05~0.20 | ||

| Max. PV | 2.8N/mm2*m/s | Thermal conductivity | 60W(m*k)-1 | ||

| Breaking Load | 350N/mm2 | Coef. of thermal expansion | 14*10-6*K-1 | ||

This material is recommended to be used under the medium speed and medium load condition with oil or grease lubricating. It is widely used for motor rod ends, kingpin bushing, undercarriage rollers, hydraulic cylinder rod eyes of construction machines and spherical joint bearings of agricultural machines.

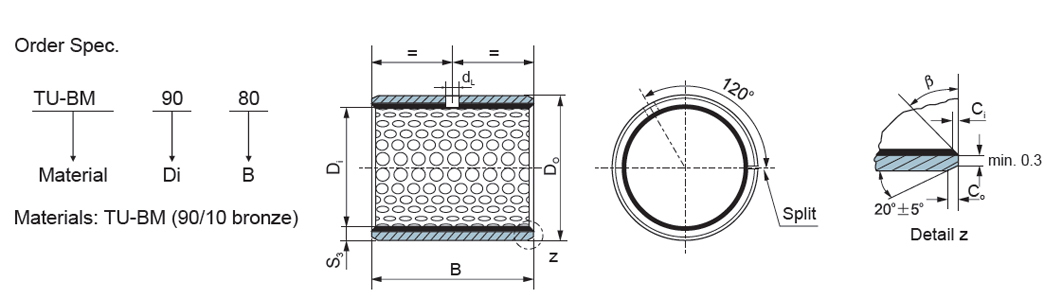

| S3 | CO | Ci | β |

|---|---|---|---|

| 1.00 | 0.6±0.3 | 0.30±0.2 | 35°±5° |

| 1.50 | 0.7±0.3 | 0.50±0.3 | 35°±5° |

| S3 | CO | Ci | β |

|---|---|---|---|

| 2.00 | 1.2±0.4 | 0.50±0.3 | 35°±5° |

| 2.50 | 1.8±0.6 | 0.60±0.3 | 45°±5° |

| Unit : mm | |||

| Di | Do | Shaft Ds h8 |

Housing H7 DH |

ID after fixed Di, a |

Clearance CD |

Wall thickness S3 |

Oil hole dL |

B0-0.40 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 15 | 20 | 25 | 30 | 40 | 50 | ||||||||

| 10 | 12 | 10-0.022 | 12+0.018 |

+0.148

+0.010

|

0.170

0.010

|

0.995

0.935

|

4 | 1010 | 1015 | 1020 | ||||

| 12 | 14 | 12-0.027 | 14+0.018 |

0.175

0.010

|

1210 | 1215 | 1220 | |||||||

| 14 | 16 | 14-0.027 | 16+0.018 | 1410 | 1415 | 1420 | ||||||||

| 15 | 17 | 15-0.027 | 17+0.018 | 1510 | 1515 | 1520 | ||||||||

| 16 | 18 | 16-0.027 | 18+0.018 | 1610 | 1615 | 1620 | ||||||||

| 18 | 20 | 18-0.027 | 20+0.021 |

+0.151

+0.010

|

0.178

0.010

|

1810 | 1815 | 1820 | 1825 | |||||

| 20 | 23 | 20-0.033 | 23+0.021 |

+0.161

+0.020

|

0.194

0.020

|

1.490

1.430

|

2010 | 2015 | 2020 | 2025 | ||||

| 22 | 25 | 22-0.033 | 25+0.021 | 6 | 2210 | 2215 | 2220 | 2225 | ||||||

| 24 | 27 | 24-0.033 | 27+0.021 | 2410 | 2415 | 2420 | 2425 | 2430 | ||||||

| 25 | 28 | 25-0.033 | 28+0.021 | 2515 | 2520 | 2525 | 2530 | |||||||

| 26 | 30 | 26-0.033 | 30+0.021 |

+0.181

+0.040

|

0.214

0.040

|

1.980

1.920

|

2615 | 2620 | 2625 | 2630 | ||||

| 28 | 32 | 28-0.033 | 32+0.025 |

+0.185

+0.040

|

0.218

0.040

|

2815 | 2820 | 2825 | 2830 | 2840 | ||||

| 30 | 34 | 30-0.033 | 34+0.025 | 3015 | 3020 | 3025 | 3030 | 3040 | ||||||

| 32 | 36 | 32-0.039 | 36+0.025 |

0.224

0.040

|

3215 | 3220 | 3225 | 3230 | 3240 | |||||

| 35 | 39 | 35-0.039 | 39+0.025 | 3520 | 3525 | 3530 | 3540 | 3550 | ||||||

| 38 | 42 | 38-0.039 | 42+0.025 | 8 | 3820 | 3825 | 3830 | 3840 | 3850 | |||||

| 40 | 44 | 40-0.039 | 44+0.025 | 4020 | 4025 | 4030 | 4040 | 4050 | ||||||